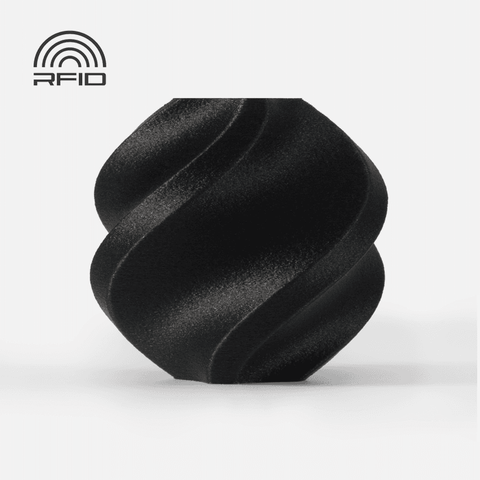

Fillamentum Flexfill 98A Filament 500g

Flexfill 98A is elastic, flexible filament. On the hardness scale, 98A stands for hard rubber - the same hardness as e.g. hard wheels of roller skates and skateboards.

Hard plastic may be a popular material, however in some situations, it can be less than ideal or even completely unsuitable. Whether you need a phone cover, an action camera case or wheels for your RC car, flexible is the way to go.

The family of flexible filaments is called TPE (ThermoPlastic Elastomer) and Flexfill 98A belongs to a subtype of TPE called TPU (ThermoPlastic Polyurethane). The main difference between them is that the general TPE is usually much more flexible, but because of that, it’s also harder to print with. TPU has similar mechanical properties as TPE, but the increased rigidity makes it easier to print with as the filament is less prone to bending in the extruder. Still, you’ll have to make some adjustments to successfully print with TPU.

First, clean the nozzle of previously extruded plastic. Next, you’ll need to empty the hotend of any plastic left inside. Normal unloading will leave some filament inside and TPU will have a very hard time pushing it out. So either do a “cold pull”, where you preheat, insert PLA, set the temperature to 85°C, loosen the idler completely and pull the filament out rapidly. Or alternatively, if you have 1.5mm wire around, you can just preheat and push the filament out with the wire.

Before you actually load TPU, loosen the extruder (idler) screws a bit. After that, you’re good to go. Flexible filaments can bond to the bed too much, especially to PEI. To prevent damage you might need to use glue on the bed as a separator (you can use the glue stick that we ship with each printer).

Flexfill has very good abrasion resistance, remains flexible in cold environments, and is resistant to many solvents. It doesn’t shrink much when cooling down, so you can be fairly accurate with your measurements and perfect fit models.

Printing Setup

| Nozzle | 220-240 °C |

| Heatbed | 50-60 °C |

Basic Attributes

ProsFlexible and elastic

Little shrinking

Good layer adhesion

Cons

Extra steps when loading filament

Can be trick to print.