Technical Specs

-

Viscosity: ~180-200 mPa·s — flows well, good for detailed prints

-

Elongation at Break: 30-40% — flexible enough for functional parts

-

Flexural Strength: ~40-50 MPa; Flexural Modulus: ~1000-1200 MPa — rigid and strong

-

Tensile Strength: ~35-45 MPa

-

Hardness: Shore ~80-85 HD

-

Heat Deflection Temperature: ~60-65 °C — stable under moderate heat

-

Shrinkage: ~4.3-5.6% — helps reduce warping/distortion

Print & Post-Processing Recommendations

-

Curing Light: UV, in the 365-405 nm range

-

Layer Thickness & Exposure: Typically ~0.05 mm with exposure times tuned per printer model

-

Cleaning: Wash in water or use alcohol/water mixture. Ultrasonic cleaners or wash-and-cure stations improve results

-

After-print Finishing: Remove supports, sand or polish if needed, then fully cure the print. Proper storage (cool, dark place) helps maintain uncured resin quality

Applications

Perfect for:

-

Functional mechanical parts

-

Snap-fits, hinges, and moving components

-

Shells or housings (e.g. for electronics)

-

Appearance prototypes & display models

-

Tools, fixtures, stress-bearing parts

Available Options

-

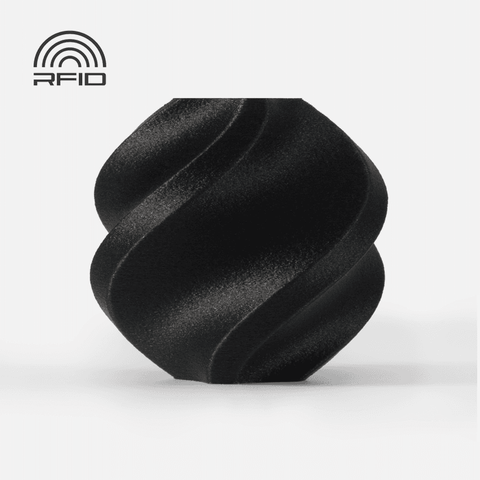

Colors: Gray, White, Black

-

Size: 1 kg bottle